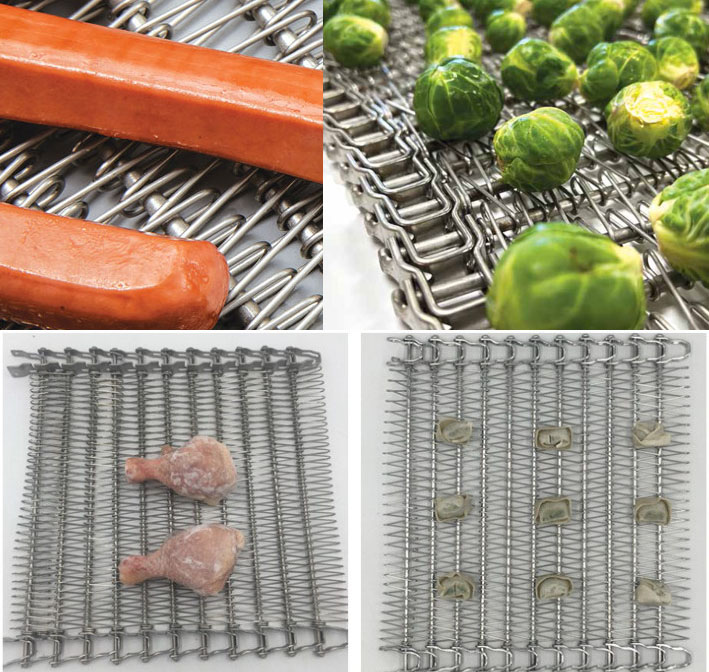

Flex Rod Conveyor belt for Freezing cooling

stainless steel wire mesh belt is especially designed for spiral or round conveyor as well as straight-running conveyor. With the ability to side flex, the belt can also be used for conveyors arranged to go around obstacles.The flexible rod belt is popular in the food industries, including cooling, cooking or freezing products.

Features :

- Wide range of pitches and turn radii

- High quality welding

- Smooth and uniform surfaces to handle the product correctly

- Cheaper than a chain driven conveyor belt

- Stainless steel

- Capability of turning / assembling

- Eliminates transfers

- Positive drive

- Simple to guide

- Easy to repair

- Temperature range

- Large width

- High speed

- Long service life

Applications:

The -flex freezing belts are mostly applied in installations whereby food products are gradually cooled or warmed in spiral shaped tower installation , such as processes as cooling, freezing, pasteurizing, smoking and cooking. However this belt can be also used as a straight lined installation,It then concerns mostly an installation for the shock-freezing of food products, for example by using the liquid nitrogen which immediately evaporates.

- Raw meat

- Poultry

- Fish

- Baked, cooked, and fried products

- Ready meals

- Soups

- Ice creams

- Desserts

- And pet foods

Specifications:

General details specifications:

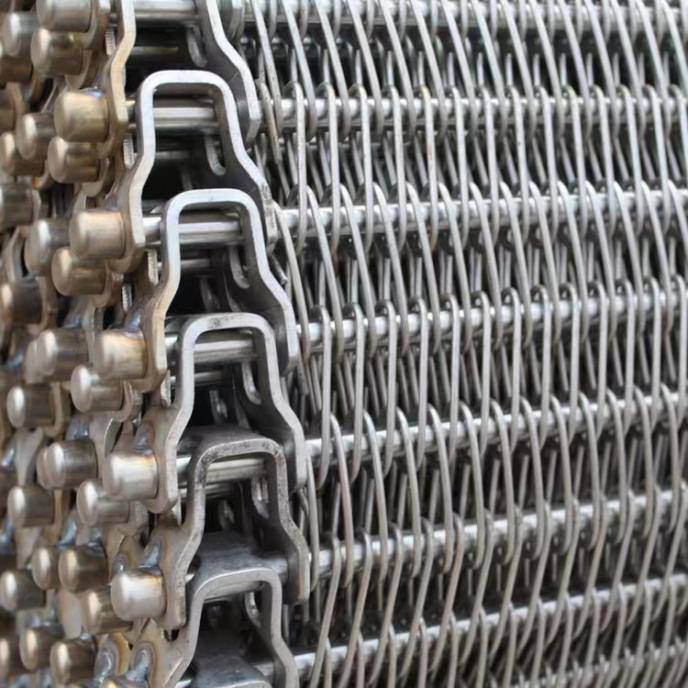

- chain pitch: 19,05 mm until 38,1 mm

- “Turn ratio”: min 1,1 – max 2,5

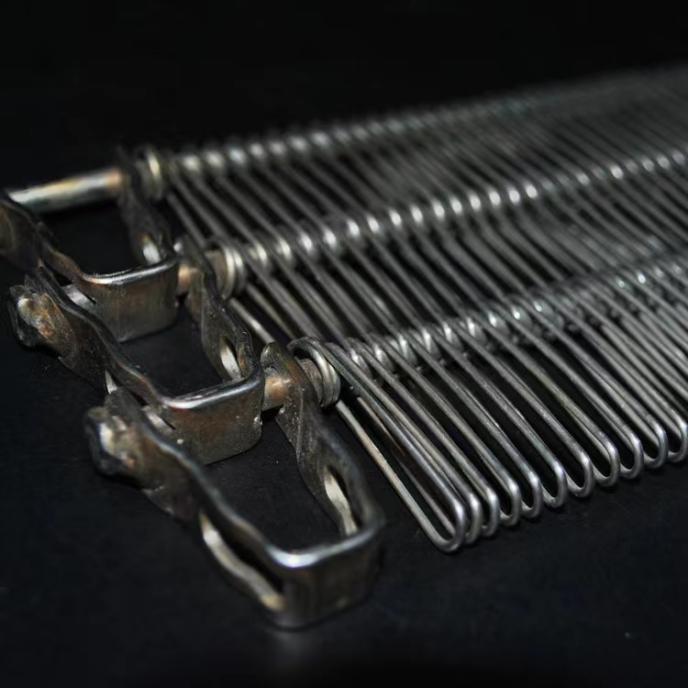

- Cross rod wire: 4,9 / 6,0 mm

- Spiral wire: / 1,2 / 1,4 / 1,6 mm in soft or spring steel wire

- Lateral pitch of the spirals: 3,0 – 25,4 mm

- Materials: 304/ 301/316L/316

- Heightened side guards are a possibility

- The chains are provided of small ’round dents’ which enables the cross rods to have a larger contact surface with the chains

- The ends of the spirals are provided with oval eyes, so called “pig tails”. This ensures that the spirals always remain their position and that there is no chance of protruded wire ends

|

|

|

|