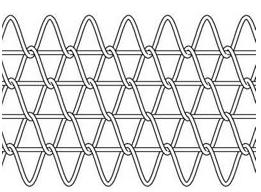

Chain Link Conveyor Belts

Chain Link belting is the simplest available wire belt design, suitable for light duty use in drying and cooling applications. Chain Link is a component part of Wire Belt Company's Troughing Filter Belts, and can also be used as collapsible screen for applications such as lift guards.

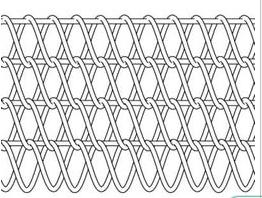

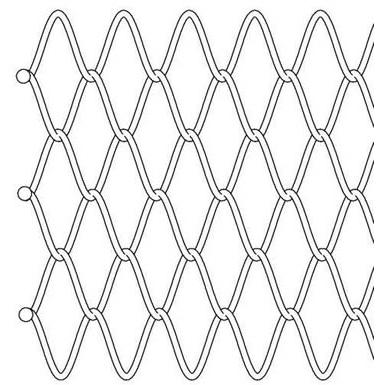

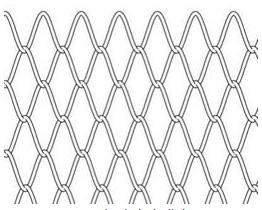

Standard chain link conveyor belt is ideal for drying, cooling and heating because it has a large area of opening area that keeps air flowing. And it also increases delivery efficiency and reduces downtime during use. Reinforced chain link conveyor belt is stronger than the standard. The reinforced rod not only increases the strength of the belt, but also keeps the belt steady during transport. Certainly, double reinforced chain link conveyor belt with a smaller opening area and greater strength.

|

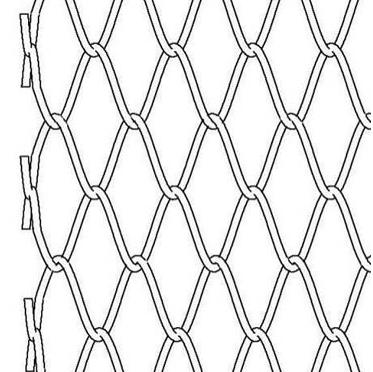

welded edge of chain link conveyor belt. |

knuckled edge of chain link conveyor belt. |

|

|

|

Features:

- Easy to install

- Easy to clean

- The most economical belt for lowload conveying applications

- Large open area idealfordrying and cooling

- Supplied with welded or knuckled edge finishes

- Simple structure, only made of several spiral coils.

- Large opening area with good air circulation, ideal for drying and cooling.

- Welded or knuckled edge for your choice.

- Side and center baffles can be added to the conveyor belt to prevent the products from falling down to the ground.

Applications:

- Cooling

- Drying

- Heating

- Industrial curtains

- Light weight Transporting

- Lift guard.

- Drainage.

- De-elevating.

- Elevating.

- Industrial furnace.

Standard Chain Link belt ,When used as a friction driven belt the assembly may feature alternating sections of left then right hand assembled panels. Each belt panel is linked to the next opposite hand weave panel with a through wire. Panelling of the belt with left & right hand coil sections help alleviate belt track off on all circuit rollers and belt supports. Many friction driven belts however are not panelled in this way and rely on their weight and the conveyor tracking system to ensure straight running of the belt

Reinforced Chain Link belt, Left and right assembly of panelled coils are linked together by a through connector pin. The alternating handing of the panelled coils balances the weave contact with the friction driven roller or idle rollers to ensure best tracking performance of the belt

Double Reinforced Chain Link belt,To add even more belt strength and reduce the open area then a duplex version of the standard rod reinforced is available. The assembly consist of twin intermeshing standard coils at each position